Hank Elwood and I collaborate on replicas of antique air guns. The following are photos from our 4 year complete build of a Lukens Air Rifle.

Inletting barrel – muzzle

Inletting barrel – breech end

Vise and workbench for inletting

Drilling ramrod hole in forestock

Ramrod hole being drilled

3 stages of inletting bronze barrels

A small assortment of Hank’s files

Forestock bottom – finished

Forging a trigger guard

Coal forge

Prototype with folded steel flask

Hank’s 18th century rifling machine replica

Prototype – lock side

Rifling machine – pull end

Hank Elwood – first shot from prototype

Hank Elwood – exercising on rifling machine

Bottom

Left

Top – gotta love that bronze!

Hank proudly displaying first finished Lukens DNH

Right

Needed 15 grooves – ‘modern’ indexing head in foreground

3 barrels being inlet for forestocks – note plaster models of original

Hank’s tooling – 18th century style

striker lever made from flat stock

Striker lever workup

Receiver and lock – double neck hammer from French pistol

Davis lock affixed to custom lockplate

Sideplate removed to show stiker lever and linkage

Full cock – striker behind lever

Striker just about to pass over lever during cocking

Half cock – striker abreast lever

receivers with wax patterns, models of original gun and furniture

Bottom view of receiver

Top view of receiver – striker ahead of lever – uncocked

Hickory rifing head with cutter, lube and shims

15 grooves as per original

Hank’s 18th century rifling machine replica

barrel clamped in 18th century rifling machine

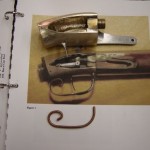

Bronze prototype casting with photo of original gun

Sideplate view of pattern

Pattern sans plates and barrel

Pattern carved and shaped

Pattern taking shape around lockplate

lockplates and mock barrel inlet into wax

Receiver rear – striker pin with linkage to striker lever visible

Interior of receiver showing transfer port