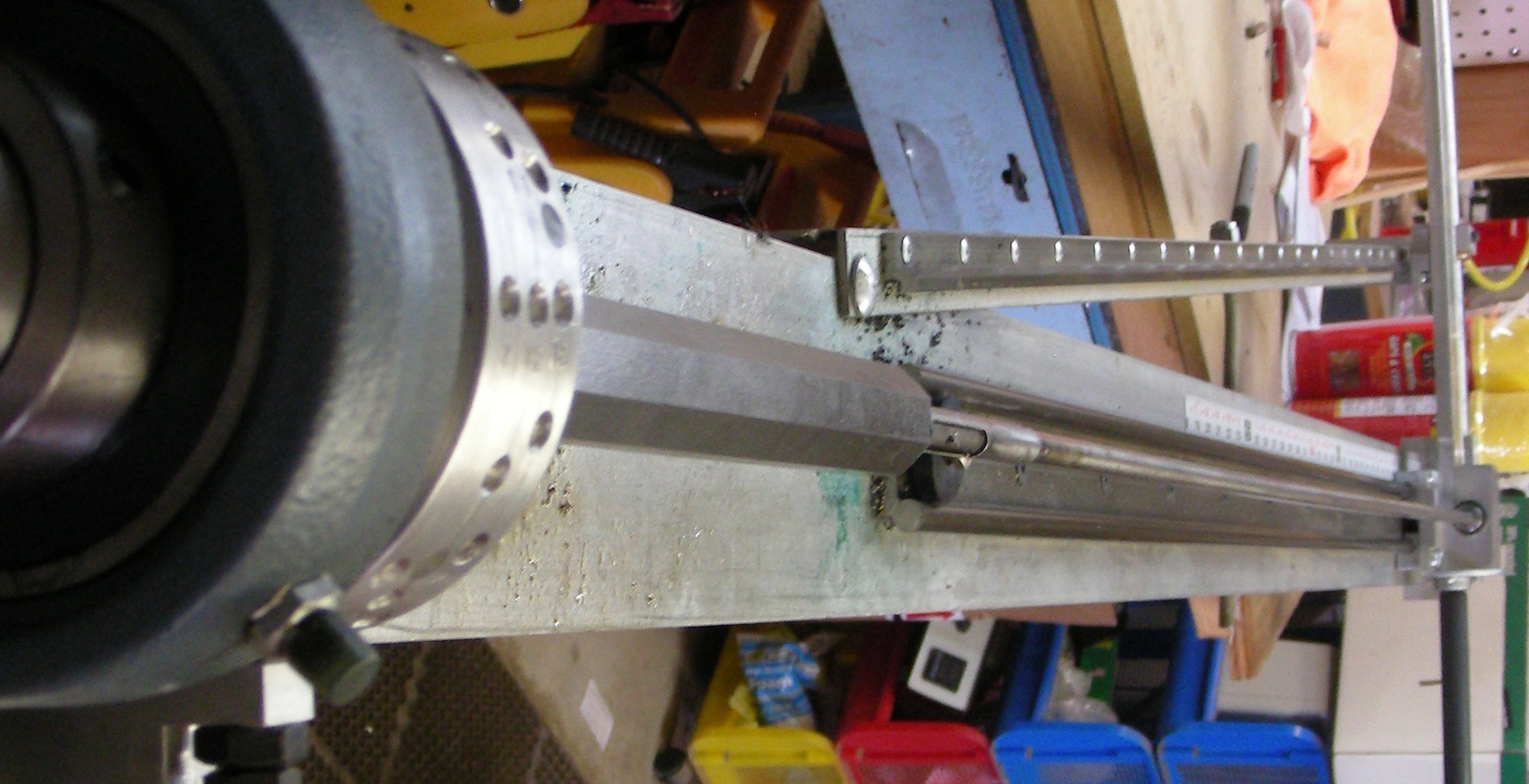

Built a new rifling head and cutter for the Girardoni rifle barrels. The design is modified from “The Modern Gunsmith” by James Virgil Howe. His design is based on a scraper rather than cutter as used on the 1902 Springfield rifle barrels. It operates/cuts in both directions. I’ve made a carbide cutter and Ag brazed it into the rifling head.

The head is placed on a rod affixed to the rifling machine and inserted into the breech of the barrel.

After pushing and pulling the head/cutter through the barrel, a very fine swarf is produced. The swarf resembles steel wool and is difficult to see and remove from ones skin.

The original Girardoni has 12 grooves and lands with a .463 groove depth. We are going for a .457 depth due to the availability of that caliber ball and molds.

Two Green Mountain .45 smooth bore, 1″ octagonal barrels were purchased. They have been rifled, cut to length, breeches reduced, threaded and indexed to fit into the breech blocks. One is stock length, the other 4″ longer. Having seen Dr. Beemans replica, I think a longer rifle might look better IMHO.

Time: 4 hours on the first barrel, 3 hours on the second. Learning curve.

Next step will be to taper the barrels. They will taper from .980″ to .750″, breech to muzzle.