Last weekend I lapped the barrels. This consists of making a close negative of the barrel bore and rifling in pure, soft lead, coating with an abrasive paste and pushing and pulling it through the barrel repeatedly. This smooths out machining marks and irregularities. Also one can determine if there are tight spots in the bore and correct them. One can also ‘choke’ or taper the muzzle end of the bore for better gas seal and accuracy.

First a ‘jag’ is made. Threaded on the left to attach to the lapping rod, grooved and knurled to securely hold on to the molten lead.

Next a string is wrapped around the threaded end. This keeps the molten lead from running past the jag down the barrel.

The jag, string and rod are shoved up the muzzle and stopped ~1 inch short of the breech and the whole thing heated to ~400 F.

Any lead overflow is cut off with a sharp knife. I told you the lead is soft.

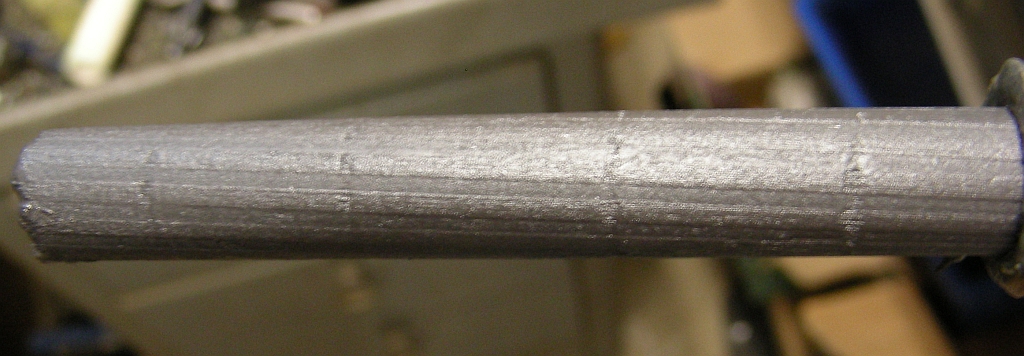

The resultant lap is pushed part way out of the barrel for inspection. Sometimes voids appear due to underheating the barrel or an uneven pour (learning curve). This is a good one…

Grooves are filed into the lap to retain the abrasive compound. The lap is coated with the lapping compound..

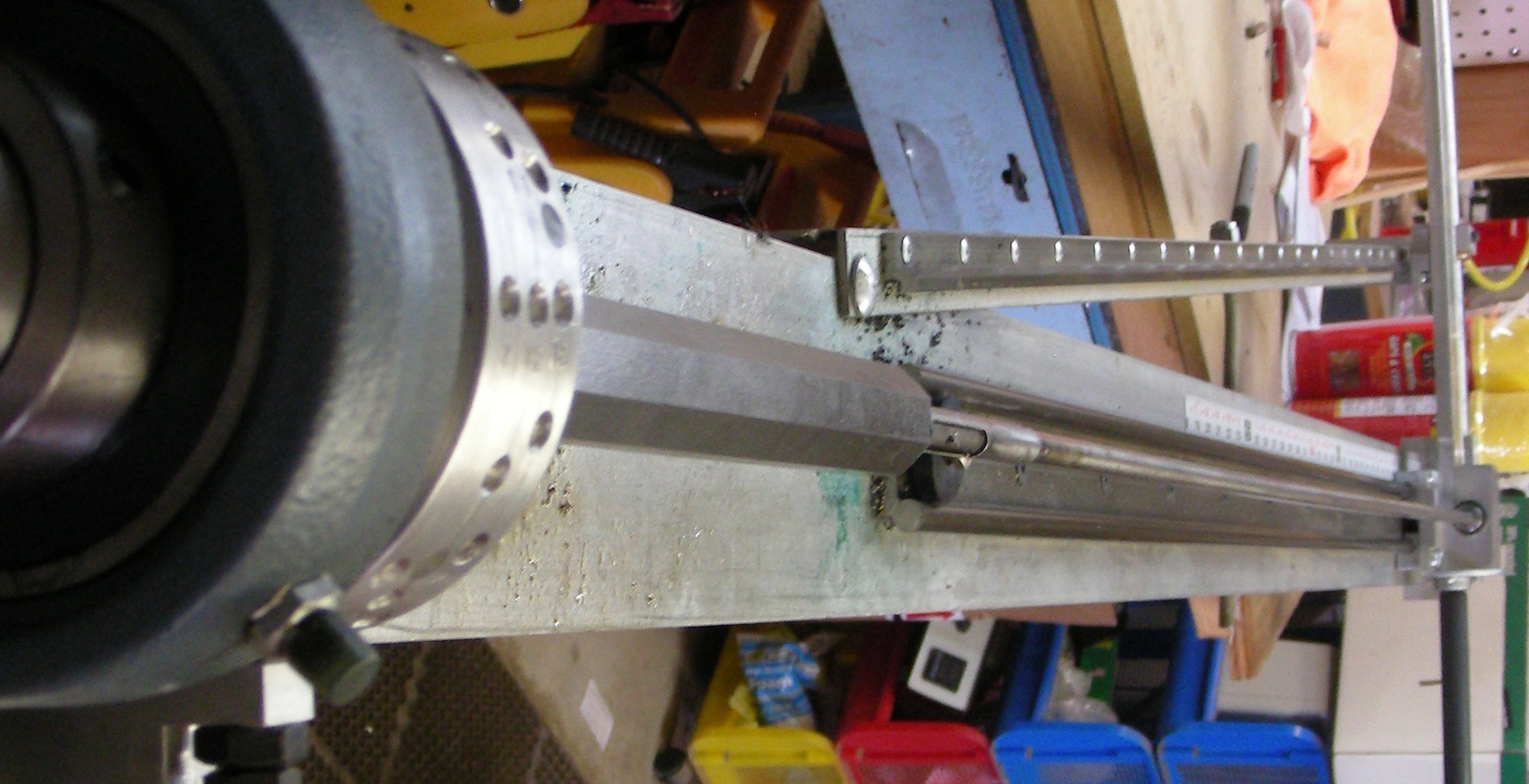

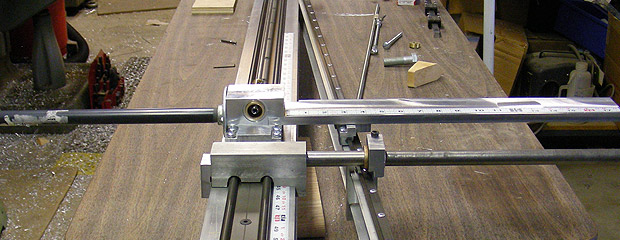

The lapping rod is attached to a handle assembly (flanged bearing bolted to 1/2″ galvanized pipe with bicycle grips). The barrel is placed in a sturdy vise. And the labor intensive part begins. This will replace rowing machines, eventually…

The lap should not leave the barrel at either end of the stroke. Otherwise it’s very difficult to get it back in properly. There is a great deal of resistance at first and each time the grit is renewed. I could feel differing resistance at certain areas of the bore which eventually became uniform. After several strokes, it looks like this..

You can see the rifling. Note the linear marks from the rifling cutter. The abrasive has embedded itself in the surface of the lead.

I used 220 and 380 grit on these barrels. Finer grits are available. You need a new lap for each grit – no mixing grits!

Here’s the bore after lapping..

And some .457″ balls after passing through the bore.. I lapped more toward the breech end and less at the muzzle. When passing balls through the barrel, one can feel them getting tighter at the muzzle. This constriction is the ‘choke’.

Now, this process involves HEAT, lead fumes and icky lapping compound. Not for the average home project.. Just what I’ve done, not that it’s the only way or even recommended!

~30minutes to make each lap (4 made, 2 per barrel, 1 each for 220 and 380 grits). ~2 hours of lapping per barrel.

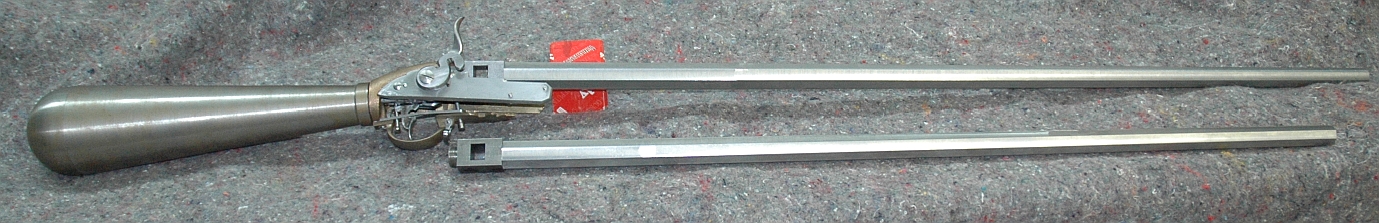

These barrels are almost ready to be inlet into the stocks. The muzzles need to be lapped, the breeches filed and polished to seat on the sliding loading bar and secured to the breech blocks.

Later… Martin